Make what matters™

3D PRINT INDUSTRIAL-STRENGTH ELASTOMERS ANYWHERE,

ON ANYTHING

ONE PART

OR ONE MILLION

Stop imagining the world you want. Start making it.

See how our technology helped fashion designer Anouk Wipprecht create a new futuristic 3D-printed dress that responds to its environment through nearly 75 LEDs.

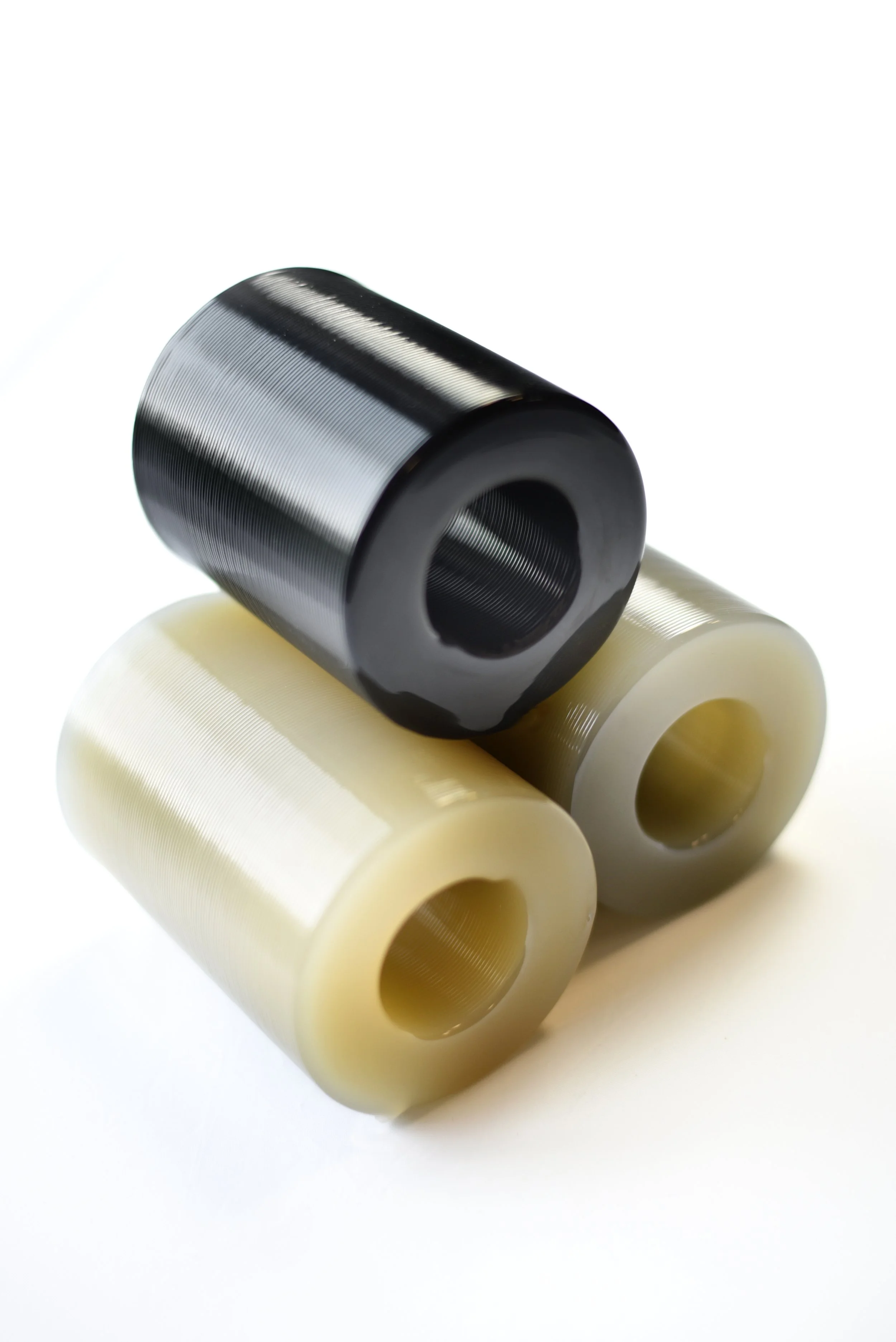

THE ADDITIVE MANUFACTURING PLATFORM FOR 3D PRINTING DURABLE RUBBER PARTS

RX-AM™ is the only materials and technology platform that lets you harness the power of chemical reactions to print industrial-strength elastomeric parts.

Get the durability you need with all the perks of additive manufacturing:

control and flexibility

lower total cost of ownership

sustainability

Plus a world of radical new design options.

Introducing RX-AM™:

With the RX-AM™ platform, you can 3D print with chemical reactions. No melting, lasers or post processing.

Material cures

as it is deposited

Liquid materials flow

through the printhead

Our production-ready printing delivers a smooth result and allows unique geometries for novel product designs.

See what our technology can do

Flexible materials you know and trust

RX-AM™ makes it possible to print products with qualified materials you know and trust. Choose from our range of thermoset polyurethane elastomers in Shore A 50-90. Fully customize flexibility, strength and color. Or let us make your existing materials printable.

Our 3D printing technology is different

Buy 3D-printed polyurethane parts

In a rush? Let us print for you. Get common parts in custom dimensions delivered in days — with no tooling costs.

Not like other

additive manufacturing

With the RX-AM™ platform, you 3D print on any substrate for new, unconventional assemblies:

metal

textile

plastics

ceramics

Polyurethane printed directly on metal

Be the first to know

Subscribe to our monthly newsletter.